Menu

Menu

Drives of the Simplified Motion Series combine the simplicity of pneumatics with the benefits of electric automation and are ideal for simple movements between two positions. The drives are operated without the assistance of any software based on the plug and work principle.

With Festo, you get a complete package for automation, from a component to a complete automation solution. With the portfolio, you’ll find everything from process, media and solenoid valves to actuators, sensors, and controllers to ready-to-install systems and integrated automation concepts. With a modular design, the plants are flexible and easy to adjust, with an integrated architecture that makes it easy to work on and with automation solutions. In addition, maximum efficiency and reliability are guaranteed.

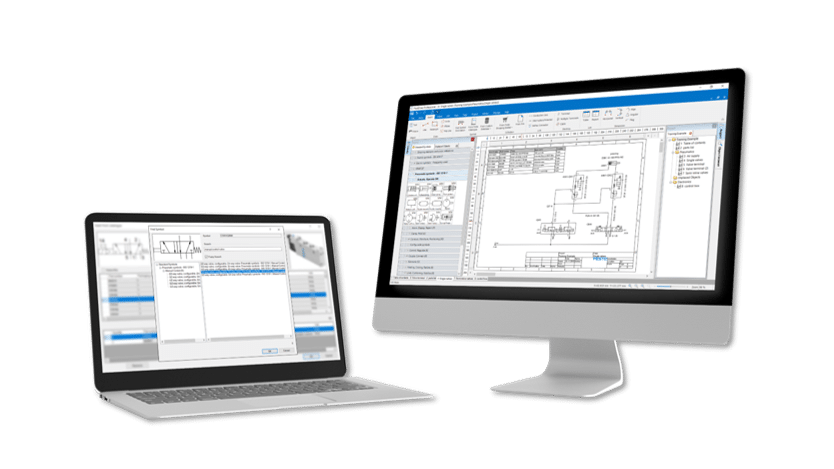

With our Technical Specialists and Festo’s FluidDraw & FluidSIM software, we can offer tailored solutions for your next project. Whether it’s a planned upgrade to an existing process automation system or a bold new design and installation. We can bring your ideas to life.

Even complex circuit diagrams that contain both pneumatic and electric components can be easily realised with FluidDraw. The software is part of the Festo engineering tools that provide users with a paperless and smooth approach for all phases, from planning to delivery and commissioning.

The Festo Core Range offers high-level functionality at an affordable price. Its 2,200 products solve most of your automation requirements and are generally ready to ship within 24 hours, even if you need large quantities.

The Simplified Motion Series from Festo combines the simplicity of pneumatics with the advantages of electric automation for simple movement and positioning tasks between two mechanical end positions. With its space-saving design, the EPCE Electric Cylinder is suitable for applications with limited installations space.

Working on a simple “plug and work” principle with integrated Digital I/O (DIO) and IO-Link (both types come as standard), the Simplified Motion Series reduces the design and commissioning process compared to traditional, often more complex electronic drive systems. No special expertise is required to complete the commissioning of Simplified Motion Series products. All the parameters (speed and force, reference end position and cushioning) are all manually set directly onto the drive via a user-friendly interface.

Pneumatically actuated pinch valve VZQA is used for controlling the flow of liquids or powdery media and solids in tubing or pipes. It is either open or closed, both of which create minimum flow resistance and prevent the fitting from becoming clogged.

VZQA Pinch Valves are ideally suited to filling systems, dosing and weighing systems, powder coating systems, suction and compressed air control units, pneumatic conveying systems and sandblast systems.

With its high flow rate, reliable pressure regulation, and corrosion-resistant stainless steel construction, this stainless steel filter regulator is one tough filter. It comes in 1/4″ and 1/2″ sizes with G or NPT thread. The temperature resistance ranges from -60 °C to +80 °C, so it can be exposed to extreme cold or heat. The patented sealing technology protects against return flow and ensures reliable exhausting. Additionally, the new PCRP-44 compact version requires even less installation space for maximum flow rates of up to 1750 l/min.

In a robust polymer housing, the MS Basic offers you the most important technical functions of compressed air preparation at an affordable price. The MS Basic is fully compatible with the MS series. This allows you to have the best possible combination of low-cost and high-end features.

Dear Valued Partner,

As of December 1st, West Vic Industrial Supplies officially becomes Aventum, with Ballarat Industrial Supplies and Bendigo Industrial Supplies to transition in Q1 2024.

This change represents a natural evolution for our companies, and together we move forward into an exciting period for our company.

There is no change to the business structure, business ownership, company ABN, or bank details, so you can be assured that you will continue to receive the same great service.

Regards,

AVENTUM